Biomass to bio-diesel plants

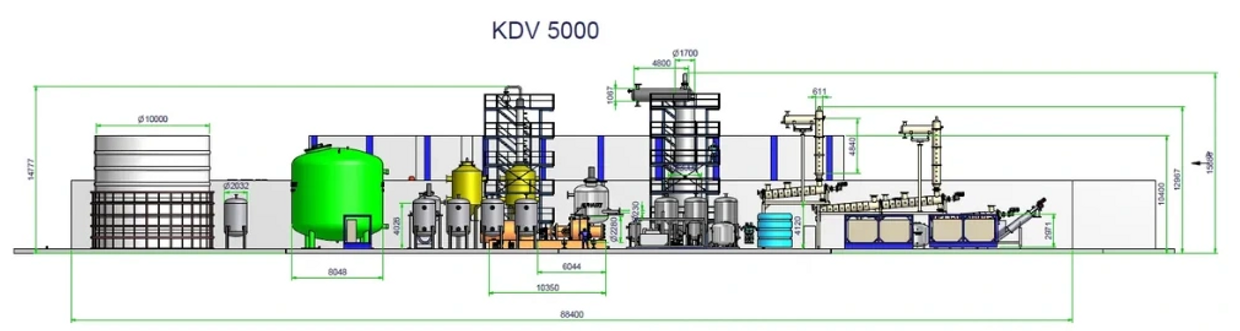

TWR KDV Biomass to Bio-Diesel System by Alphakat

What is KDV? This comes from the German words "Katalytische, Drucklose, Verölung" which mean "Low Temperature, Pressure-less, High Efficient Process" This is how it processes residues from waste with a catalytic de-polymerization process, as the basis of extracting clean fuel.

Our Goal

We specialize in providing customized solutions for your clean energy business needs. Our team of experts has a deep understanding of the global market and can help you achieve your clean energy goals.

TWR - KDV Biomass to bio-diesel plant

Acceleration of the natural time intensive transformation process from 300 million years to 3 minutes using Alkat technology. 100% 100% crystalline catalyst instead of minerals (clay soil). 280 – 330 Cº max temperature instead of natures 4Cº.

- Primary production of diesel for engines, jet fuel for turbines. Secondary production of electricity (Peak Load) and purposes of biochemistry.

- Production of distilled water.

Autonomic production process: No additional Energy, water or light needed. The installation consumes aprox. 5‐15% of its own Diesel production.

- No Dioxins

- No CO2 (CO2 is recycled except for the exhaust of the generator) Any kind of biological material, or waste, can be processed (except for glass, stones, ceramics or metal)

- Heat of 300º Celsius is re‐entered in the dehydration process. (lower heat pollution)

- ‐0,1 bar low pressure (No risk of explosion).

- PH – 9 ( no corrosion of the components of the installation)

- Emissions: The installation is a closed system (no chimney).

System functionality

About THE WORLD RESOURCE FOUNDATION

Advantages

Advantages

Advantages

• Technological imitation of the natural oil synthesis realized in minutes

• Synthetic fuel can be produced at competitive costs

•The quality of diesel is higher than the EU standard for diesel fuel .

•No polluting residues. The technology integrates inorganic harmful substances in salt

•Environmental protection, energy production and creation of jobs are combined by the use of our technology

Highlights

Advantages

Advantages

Through this process, it is possible to use all hydrocarbon containing materials – with reduced concentration of water and inorganic materials. • The efficiency of the process is very high with an effect degree of 65‐85% at a low reaction temperature (280ºC). The plant produces no coke, coal, resins, furans, olefins, etc., as well as inj

Through this process, it is possible to use all hydrocarbon containing materials – with reduced concentration of water and inorganic materials. • The efficiency of the process is very high with an effect degree of 65‐85% at a low reaction temperature (280ºC). The plant produces no coke, coal, resins, furans, olefins, etc., as well as injurious gases. The plant requires no cleaning system even running under full load.

production

Industrial Plant MSW Tarragona

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.